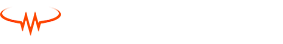

No matter which industry you are in, both repair & maintenance are equally important for assets & equipment.

We can help you to keep facility assets, equipment in good shape and performing efficiently, and avoid unplanned downtime or equipment failure.

We offer total repair and maintenance assistance for Plant Conventional & CNC M/cs.

Repairs are restoration work for when an asset breaks, gets damaged, or stops working. Maintenance refers to routine activities and/or corrective or preventive repair done on assets to prevent damage and prolong the life expectancy.

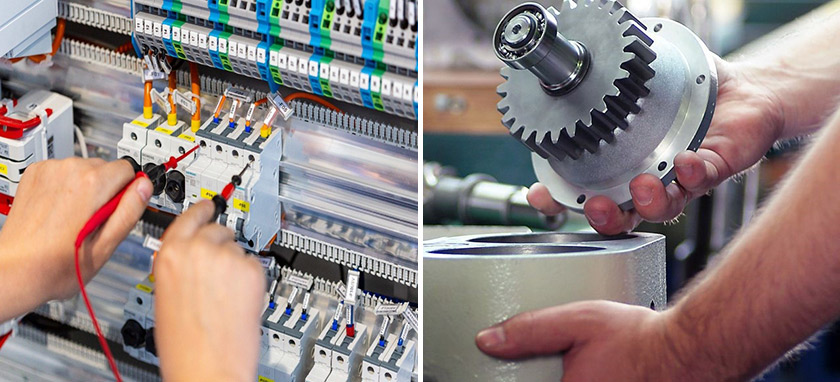

Types of Maintenance

Maintenance covers all maintenance work performed on assets. maintenance activities include visual inspections, functional checks, spare parts replacements, and installing a new asset in a facility and many more.

- Reactive maintenance: Also known as breakdown or run-to-failure, reactive maintenance is when assets get fixed as they break.

- Preventive Maintenance: Also known as proactive maintenance, this method involves taking assets offline and inspecting or repairing them at predetermined intervals (usually time or event-based triggers). This approach aims to extend the useful life of an asset and prevent breakdowns from occurring.

- Predictive Maintenance: Predictive maintenance aims to predict failures before they happen so maintenance can occur at just the right time. It uses data from machine sensors and smart technology to alert the maintenance team when a piece of equipment is at risk of failing.

- Reliability-centered maintenance: Reliability-centered maintenance addresses the fact that failure is not always linear. This type of maintenance involves analyzing all the possible failure modes for each piece of equipment and creating a customized maintenance plan for each individual machine. The ultimate goal of RCM is to increase equipment availability or reliability.